Diagnostics and Repair of Expensive Office Printers With Fuji Prescale Films

Keywords: office printers maintenance,office copiers diagnostics, printing equipment defect removal Summary: Repairing expensive office printers and copiers with the trial-and-error method is time consuming and expensive. Fuji Prescale helps repair technicians quickly diagnose the defect and repair it without unnecessary procedures and spare parts. Written by Igor MateskiPrinting Equipment Defects

Office printing equipment like networked printers and photo coppers run on laser imaging units that use transfer belts and rollers to create printouts. Since the rollers are in constant motion, they are subject to wear and tare, and eventually this leads to a failure of the imaging unit.

Failures usually occur on the development rollers because these are subject to pressure and high temperature. Failures include:

- Damage of the surface of the rollers

- Damage of the plastic bearings of the rollers

- Roller misalignment caused by paper jams or other forceful operation of the machine (human error)

Using Fuji Prescale Films as a Diagnostic Tool

As professional office printing equipment can cost up to tens of thousands of dollars, repairing these imaging unit defects is the best way to protect this big investment and keep the machine in operating order for longer periods.

When an office printer breaks, repair technicians rely on the noises and printouts to properly diagnose the problem. However, this process almost always relies on trial and error, which is time consuming, and also costly because of the high prices of replacement parts.

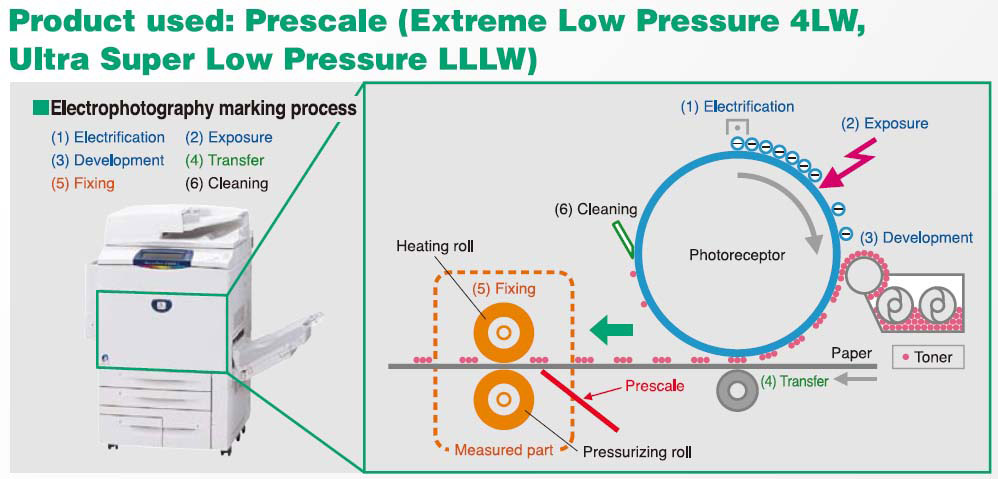

The Fuji Prescale Extreme Low Pressure (4LW) or the Ultra Super Low Pressure (LLLW) sensitive films can help with the proper diagnosis so that no time and repair parts are wasted.

The image above shows how the Fuji Prescale can be used in diagnosing and repairing office printers.

There are two ways to use the Fuji Prescale in the diagnostics process:

- Nip pressure checking of the rollers without rolling them

- Roller-surface checking by rolling the rollers (or just putting the prescale film in regular print, because it has enough temperature resistance and can withstand the development temperature in laser printers)

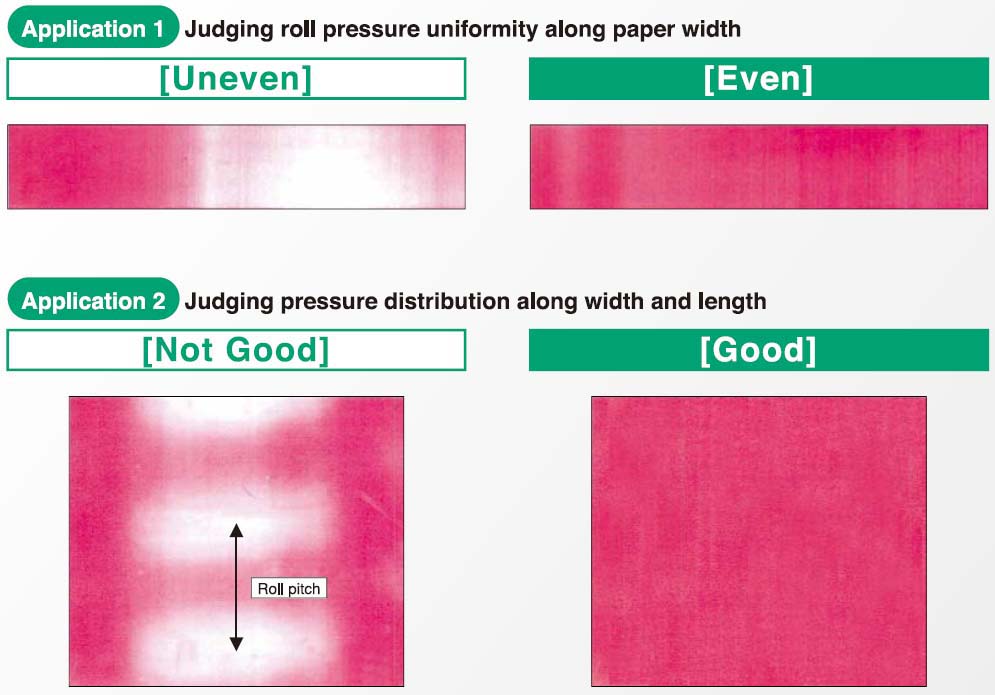

In the first application, the nip impression will reveal if the rollers axis are in proper horizontal and vertical alignment. If the developed fuji prescale film reveals evenly distributed pressure and the printout's axis is perpendicular to the edges of the film, then the rollers are properly aligned.

In the second application the roller surfaces are tested for any surface defects, but this application also will show any horizontal alignment issues if any.

The image below represents the developed films from tests with the first and second application.

In the first application testing, the image on the left reveals a defective roller alignment where one side of the roller is significantly more pressure-loaded than the other side. This will cause poor printouts and paper jams. The image to the right represents how a properly aligned rollers set will develop a nip impression fuji film.

In the second application developed films, the image on the left shows a roller defect where one area of the roller is creating more pressure than another. This will cause paper jams and intermittent printed and non-printed areas on the sheets of paper.

Benefits of Using Fuji Prescale to Diagnose and Repair Printers and Copiers

With the common defects in printers and copiers, repair technicians rely on their experience in guessing what may be the most common problem. But new models push out old ones and technology is moving forward, so best-guessing sometimes can lead in many hours of trials and errors and experimenting with expensive spare parts.

Thanks fo the Fuji Prescale films, the guesswork is eliminated from the diagnostics process:

- Precise measurement of roller alignment

- Quick assessment of the pressure distribution profile of the roller assembly

- Easy method of scanning the roller surface for defects

With these diagnostics aids, repair technicians can precisely diagnose the problem and repair it in a lot shorter time than by using the old trial-and-error approach. Fuji Prescale should be in any printer repair technician's toolbox.